With its BALIS project, the German Aerospace Center (Deutsches Zentrum fur Luft- und Raumfahrt; DLR) is developing the world’s first fuel cell powertrain for aircraft with an output in the megawatt range.

In doing so, DLR is taking another step towards making hydrogen-powered, emission-free flight possible. Steffen Bilger, Parliamentary State Secretary at the Federal Ministry of Transport and Digital Infrastructure (Bundesministerium fur Verkehr und digitale Infrastruktur; BMVI), presented the funding decision for the BALIS project – a total of 26 million euros – to the DLR Institute of Engineering Thermodynamics in Stuttgart during an online event on 21 January 2021.

“In this decade, it is a matter of shifting gears and transitioning our transport to carbon-dioxide-free or low-carbon fuels. Mobility with hydrogen from renewable energy sources will play an essential part in this. Hydrogen can be used as a fuel for all modes of transport, including aircraft. The goal is emission-free air transport, preferably whilst also creating jobs and added value in Germany,” Bilger said when he presented the funding.

“Whether in the air, on the road, on rails or at sea, DLR is one of the pioneers in the development and application of fuel cells and can draw on expertise and experience from years of research. With projects such as BALIS, we are also setting standards for the future, moving towards emission-free mobility based on hydrogen as a further pillar in our energy system,” explained Karsten Lemmer, the member of the DLR Executive Board responsible for energy and transport.

“The BALIS project demonstrates that hydrogen-powered propulsion in air transport is realistic and feasible. We are thus continuing the success story of the ‘National Innovation Programme Hydrogen and Fuel Cell Technology’ (NIP).

Through NIP, the ‘National Organisation for Hydrogen and Fuel Cell Technology’ (NOW) and ‘Project Management Julich’ (Projekttrager Julich; PtJ) have been systematically developing hydrogen and fuel cell technologies from the research and development stage to market maturity since 2008, using funding from the German Federal Ministry of Transport.

NIP has been a pillar of the national hydrogen strategy. Germany can only effectively participate in a global hydrogen economy with innovative technologies,” says Kurt-Christoph von Knobelsdorff, Managing Director of NOW GmbH.

Focusing on a fuel cell powertrain and a unique test environment

The aim of the BALIS project is to develop and test a fuel cell powertrain with an output of approximately 1.5 megawatts. This would be enough to allow the development of a regional aircraft with 40 to 60 seats and a range of 1000 kilometres.

For this purpose, DLR is constructing a unique test facility. It forms the necessary overall system, namely the complete hardware and the essential infrastructure, including the fuel cell system itself, the hydrogen tanks, the electric motor and the control technologies. This test environment is simultaneously complex and extremely flexible. It enables research and development under the most diverse conditions, requirements and guidelines applicable to the air transport sector.

“With BALIS, we are creating the foundation for energy conversion technology by developing an initial demonstration system in the 1.5 megawatt power class and working out the optimal mode of operation. Next, we want to transfer the technology into practical applications together with partners from research and industry,” explains Andre Thess, Director of the DLR Institute of Engineering Thermodynamics.

Thess adds: “The initial focus is on its use in air transport. However, such fuel cell systems can also be used in heavy-duty transport, for example in large commercial road vehicles, in trains or on ships.”

Sound barrier at 1.5 megawatts – a new generation of fuel cell systems

Most fuel cells that are already commercially available have an output of 100 to 200 kilowatts per module. To reach the megawatt range, however, it is not possible to combine any number of smaller systems. This is where the technology reaches its limits.

“There is a ‘sound barrier’ at 1.5 megawatts as far as the architecture and performance of current fuel cell system components are concerned,” says Josef Kallo, a DLR expert on the use of hydrogen in air transport.

“We want to exceed this limit and simultaneously bring together as few high-power fuel cell stacks as possible. To do this, we need novel approaches and new components, for example in optimised current-density distribution, voltage level, the handling of liquid hydrogen in large quantities and coupling to an overall propulsion system.”

Related Links

DLR Institute of Engineering Thermodynamics

Powering The World in the 21st Century at Energy-Daily.com

|

We need your help. The SpaceDaily news network continues to grow but revenues have never been harder to maintain. With the rise of Ad Blockers, and Facebook – our traditional revenue sources via quality network advertising continues to decline. And unlike so many other news sites, we don’t have a paywall – with those annoying usernames and passwords. Our news coverage takes time and effort to publish 365 days a year. If you find our news sites informative and useful then please consider becoming a regular supporter or for now make a one off contribution. |

||

|

SpaceDaily Contributor $5 Billed Once credit card or paypal |

SpaceDaily Monthly Supporter $5 Billed Monthly paypal only |

|

![]()

Russian chemists developed polymer cathodes for ultrafast batteries

Moscow, Russia (SPX) Jan 20, 2021

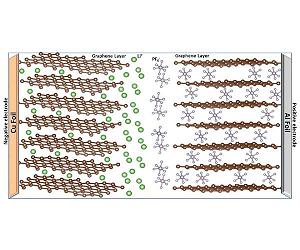

In the face of the surging demand for lithium-ion batteries and limited lithium reserves, scientists are searching for lithium technology alternatives. Russian researchers from Skoltech, D. Mendeleev University, and the Institute of Problems of Chemical Physics of RAS have synthesized and tested new polymer-based cathode materials for lithium dual-ion batteries.

The tests showed that the new cathodes withstand up to 25,000 operating cycles and charge in a matter of seconds, thus outperforming lith … read more