Volkswagen celebrated Thursday the beginning of work on its first in-house battery factory, as the German auto giant looks to head off competition from US and Chinese electric vehicle upstarts.

The firm plans to “steer the worldwide battery offensive” from the new plant in Salzgitter in central Germany, CEO Herbert Diess told a ceremony attended by German Chancellor Olaf Scholz.

Volkswagen has set itself the ambitious aim of becoming the world’s biggest electric car manufacturer by 2025, pouring a total of 46 billion euros ($46.8 billion) over the next five years into the drive.

“If Germany and Europe don’t want to be left behind by the US and China, we need to focus more on the technologies of the future,” Diess said.

The Salzgitter complex, where currently thousands of combustion engines roll off the factory line every day, is set to be the centre of Volkswagen’s electric ecosystem.

Two billion euros are being invested in the battery plant through 2026, with the potential for the site to turn out batteries for 500,000 vehicles a year.

The plan will also serve as a blueprint for a fleet of battery plants in Europe.

– ‘Sustainable, climate-compatible’ –

Up until now both legacy carmakers like Volkswagen have largely relied on Asian, notably Chinese, battery makers to fit their vehicles.

Western auto giants are keen to bring production in house, to minimise supply disruptions and pocket the added value from battery production.

“Reliance” on distant suppliers had shown itself to be a “big risk” for manufacturers, said Scholz, who placed the last unit of a ceremonial foundation battery.

“Today is a good day for the automotive industry in Germany and Europe,” he said, adding that VW was paving the way in “sustainable, climate-compatible mobility”.

Scholz said Europe’s top economy aimed to have 15 million electric vehicles on its streets by 2030.

Volkswagen’s new PowerCo unit plans to invest more than 20 billion euros together with partners, with the aim of generating annual sales in excess of 20 billion euros and employing up to 20,000 people in Europe alone. Around 5,000 will be employed in Salzgitter.

In total, Volkswagen plans to open six plants together with partners in Europe, with another to come in the United States, according to Diess.

The first, a collaboration with battery maker Northvolt, will open in 2023 in Sweden, followed by the Salzgitter site in 2025.

Volkswagen has tapped Valencia, in Spain, to house a battery plant, with discussions under way for other locations in other existing production locations in Europe.

Key competitor Tesla opened its first European factory outside Berlin earlier this year. The site in Gruenheide is set to be complemented by its own battery plant.

sea-dlc/rl

Related Links

Powering The World in the 21st Century at Energy-Daily.com

|

We need your help. The SpaceDaily news network continues to grow but revenues have never been harder to maintain. With the rise of Ad Blockers, and Facebook – our traditional revenue sources via quality network advertising continues to decline. And unlike so many other news sites, we don’t have a paywall – with those annoying usernames and passwords. Our news coverage takes time and effort to publish 365 days a year. If you find our news sites informative and useful then please consider becoming a regular supporter or for now make a one off contribution. |

||

|

SpaceDaily Contributor $5 Billed Once credit card or paypal |

SpaceDaily Monthly Supporter $5 Billed Monthly paypal only |

|

![]()

These energy-packed batteries work well in extreme cold and heat

San Diego CA (SPX) Jul 06, 2022

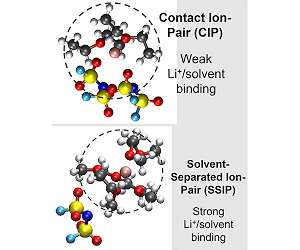

Engineers at the University of California San Diego have developed lithium-ion batteries that perform well at freezing cold and scorching hot temperatures, while packing a lot of energy. The researchers accomplished this feat by developing an electrolyte that is not only versatile and robust throughout a wide temperature range, but also compatible with a high energy anode and cathode.

The temperature-resilient batteries are described in a paper published the week of July 4 in Proceedings of the Na … read more